|

The lower back

corners of '32's look rather unfinished. George decided he wanted

some corners made like the one's we did on his roadster and John's

roadster. It really helps finish off this area better.

|

|

We start by making the top piece. This

is the area that will bolt on to the lower part of the body. Three

bolts will hold the corner in place.

|

|

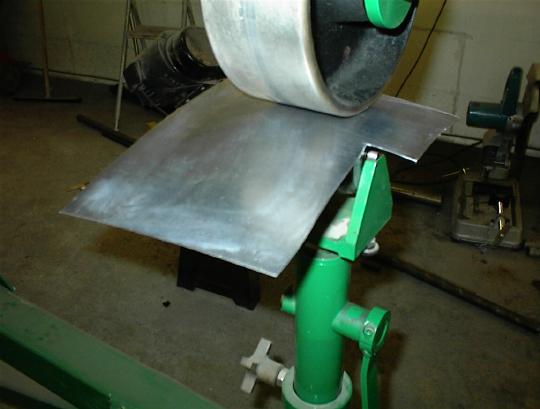

We then move on to making the body of the piece. The back

half is worked in an English wheel in order to provide the compound curve

required in this area.

|

|

Once the desired look is met, it is TIG welded

into place. Now on to making the front half.

|

|

This piece has a curved, turned-out section,

which is hammered in using a standered shot filled leather bag. Once

it's fit, it's TIG welded into place.

|

|

From there, we weld in a 1" finishing

edge to the areas that are close to the tank and frame. This gives it

a nice, finished look. Also add a drain hole at this time.

|

|

Here's a shot of the finished piece, ready

for primer and paint.

|

|

Sure helps this area look more finished.

|

|

The other side is then made to duplicate the

first one.

|